Pompalar, enerjiyi kullanarak sıvıları bir noktadan diğerine taşımaya yarayan mekanik cihazlardır. Pompaların temel kullanım alanı, gazlar, yağlar ve su gibi sıvıların taşınmasıdır. Bir çark veya pervane, sıvıların cihaz içerisinde hareket etmesine yardımcı olan pompa parçasıdır.

Üç temel pompa türü vardır: pozitif deplasmanlı, santrifüj ve eksenel akışlı pompalar. Santrifüj pompalarda, sıvı çark üzerinden akarken akış yönü doksan derece değişir; buna karşılık, eksenel akışlı pompalarda akış yönü değişmeden kalır.

FARKLI POMPA TÜRLERİ VARDIR, BUNLARDAN BAZILARI ŞUNLARDIR:

- Santrifüj Pompalar

- Diyaframlı Pompalar

- Dişli Pompalar

- El Pompaları

- Loblu Pompalar

- Manyetik Tahrikli Pompalar

- Dozajlama Pompaları

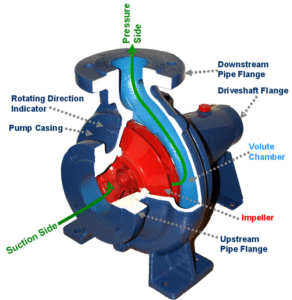

Santrifüj Pompalar :

Santrifüj pompalar, döner kinetik enerjinin sıvı akışının hidrodinamik enerjisine dönüştürülmesi yoluyla sıvıların taşınmasında kullanılır. Bu döner enerji genellikle bir motor ya da elektrikli motordan sağlanır. Santrifüj pompalar, dinamik, eksenel simetrik ve enerji emici türbomakinelerin bir alt sınıfıdır. Sıvı, pompa çarkına dönen eksene paralel ya da yakın bir yönden girer, çark tarafından hızlandırılır ve radyal olarak dışa doğru bir difüzör veya volüt odasına (gövdeye) yönlendirilir, buradan da çıkış yapar.

Yaygın kullanım alanları arasında su, atık su, tarım, petrol ve petrokimya sektörlerinde yapılan pompalama işlemleri yer alır. Santrifüj pompalar, yüksek debi kapasiteleri, aşındırıcı çözeltilerle uyumlulukları, karıştırma yetenekleri ve nispeten basit mühendislik yapıları nedeniyle sıklıkla tercih edilir.

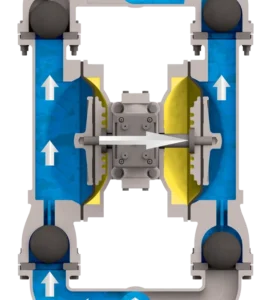

Diyaframlı Pompalar:

Diyaframlı pompa (membran pompası olarak da bilinir), bir sıvıyı pompalamak için kauçuk, termoplastik veya teflon diyaframın ileri-geri hareketi ile diyaframın her iki tarafında yer alan uygun vanaların (çekvalf, kelebek vana, klape vana veya diğer türde kapatma vanaları) birleşimini kullanan pozitif deplasmanlı bir pompadır.

Üç ana diyaframlı pompa türü vardır:

- Diyaframın bir yüzü pompalancak sıvı ile, diğer yüzü ise hava veya hidrolik sıvı ile temas halinde olacak şekilde sızdırmaz biçimde çalışanlar. Diyaframın esnemesiyle pompa odasının hacmi artar ve azalır.

- Diyaframın tahrikini krank veya dişli motor tahriki ile çalışan elektromekanik ya da kol veya manivela gibi tamamen mekanik yollarla gerçekleştiren hacimsel pozitif deplasman yöntemini kullananlar. Bu yöntemde diyafram basit mekanik hareketle esnetilir ve diyaframın bir yüzü havaya açıktır.

- Pompalancak sıvının diyaframın her iki yüzeyinde de bulunduğu, bir veya daha fazla sızdırmaz olmayan diyafram kullananlar. Bu diyafram(lar) yine esnetilerek hacim değişimi sağlanır.

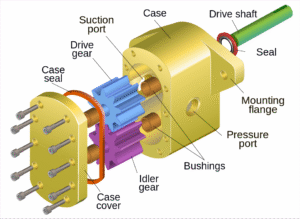

Dişli Pompalar:

Dişli pompalar, yüksek viskoziteli sıvıların pompalanması için kimyasal tesislerde yaygın olarak kullanılır. İki ana türü vardır: Dıştan dişli pompalar (iki dış düz dişli kullanır) ve içten dişli pompalar (bir dış ve bir iç düz dişli kullanır; iç dişlinin dişleri içe dönüktür). Dişli pompalar, her bir dönüşte sabit miktarda sıvı pompalayan pozitif deplasmanlı (ya da sabit deplasmanlı) pompalardır. Bazı dişli pompalar hem motor hem de pompa olarak çalışacak şekilde tasarlanmıştır.

El Pompaları:

El pompaları, elle çalıştırılan pompalardır; sıvı veya havayı bir yerden başka bir yere taşımak için insan gücünü ve mekanik avantajı kullanırlar. Dünyanın her ülkesinde çeşitli endüstriyel, denizcilik, sulama ve hobi amaçlı faaliyetlerde yaygın olarak kullanılırlar. Piyasada farklı türde birçok el pompası bulunmaktadır; bunlar genellikle piston, diyafram veya döner kanat prensibine göre çalışır ve pompa odasının giriş ve çıkışında ters yönlerde çalışan çekvalfler içerir. El pompalarının çoğu pistonlu veya dalgıçlı pompa türündedir ve pozitif deplasmanlıdır.

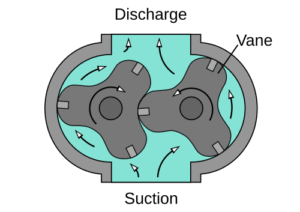

Loblu Pompalar:

Loblu pompa ya da döner loblu pompa, bir tür pozitif deplasmanlı pompadır. Dişli pompalara benzer şekilde çalışır; ancak loblar birbirine temas edip dönmek yerine, birbirine çok yaklaşacak şekilde tasarlanmıştır. Loblu pompalar; kâğıt ve selüloz, kimya, gıda, içecek, ilaç ve biyoteknoloji gibi çeşitli sektörlerde kullanılır. Bu farklı endüstrilerde yaygın olarak tercih edilmelerinin nedeni; mükemmel hijyen özellikleri, yüksek verimlilik, güvenilirlik, korozyon direnci ve yerinde temizlik/sterilizasyon (CIP/SIP) özellikleri sunmalarıdır.

Döner pompalar; katı parçacıklar (örneğin kiraz ve zeytin), bulamaçlar, macunlar ve çeşitli sıvılarla çalışabilir. Islatıldıklarında, kendi kendine emiş (self-priming) kabiliyetine sahiptirler. Nazik pompalama hareketi, ürünün zarar görmesini en aza indirir. Ayrıca, sürekli ve aralıklı ters akış sağlayabilirler ve kısa süreliğine kuru çalışmaya dayanabilirler. Akış hızı, proses basıncındaki değişimlerden büyük ölçüde etkilenmez; bu da çıkışın nispeten sabit ve sürekli olmasını sağlar.

Rotary pumps can handle solids (e.g., cherries and olives), slurries, pastes, and a variety of liquids. If wetted, they offer self-priming performance. A gentle pumping action minimizes product degradation. They also offer continuous and intermittent reversible flows and can operate dry for brief periods of time. Flow is relatively independent of changes in process pressure, too, so output is relatively constant and continuous.

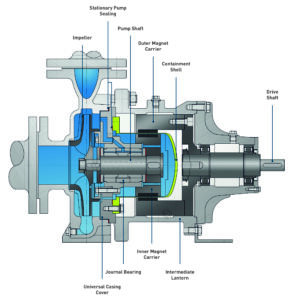

Manyetik Tahrikli Pompalar:

Manyetik tahrikli pompalar, motor ile çark arasında sızdırmazlık sağlamak için mıknatıs kullanan pompa türleridir; bu sayede geleneksel mil keçesine (sızdırmazlık elemanına) ihtiyaç kalmaz. Bu tasarım, sızıntı ve kontaminasyonu önler; bu nedenle korozyona uğratıcı veya tehlikeli sıvıların taşınmasında çeşitli sektörlerde ideal bir çözümdür. Diğer pompalar genellikle doğrudan tahrik mekanizması kullanır; bu, milin doğrudan çarka bağlı olduğu anlamına gelir. Ancak manyetik tahrikli (mag-drive) pompalarda bu bağlantı yoktur. Bu da zamanla sızdırabilecek veya arızalanabilecek bir conta bulunmadığı anlamına gelir. Böylece agresif ve aşındırıcı kimyasallar güvenle pompalanabilir.

Dozajlama Pompaları:

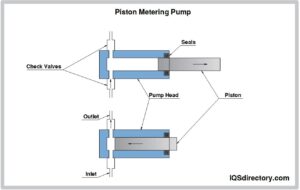

Dozajlama pompası, belirli bir zaman aralığında hassas bir sıvı hacmini hareket ettirerek doğru ve kontrollü bir hacimsel debi sağlar. Sıvıların belirli ve ayarlanabilir akış hızlarında iletilmesi işlemine genellikle “dozajlama” denir. “Dozajlama pompası” terimi, kullanılan pompa türünden çok, uygulama veya kullanım amacına dayalıdır; ancak bazı pompa türleri, diğer türlere göre bu iş için çok daha uygundur.

Dozajlama pompaları su pompalayabilse de, genellikle kimyasal maddeler, çözeltiler veya diğer sıvıların transferi için kullanılır. Pek çok dozaj pompası, yüksek basınçlı çıkışa pompalama yapabilecek şekilde tasarlanmıştır. Bu pompalar genellikle geniş bir çıkış basıncı aralığında, zamana göre ortalama alındığında sabit kalan debilerle çalışmak üzere üretilmiştir. Üreticiler, her pompa modeli için garanti edilen maksimum çıkış basıncı değerini belirtir.

Mühendis, tasarımcı veya kullanıcı; uygulamanın basınç ve sıcaklık gereksinimlerinin yanı sıra pompayla temas edecek sıvının türüne uygun malzeme seçimini de mutlaka göz önünde bulundurmalıdır.

Çoğu dozajlama pompası bir pompa kafası ve bir motordan oluşur. Pompalanan sıvı, giriş hattından geçerek pompa kafasına ulaşır ve çıkış hattından dışarı çıkar. Motor genellikle pompa kafasını çalıştıran bir elektrik motorudur.